CERTEX: We Set the Standard for Wire Rope Slings

Wire rope slings are used extensively within the industrial lifting industry. Wire rope slings, sometimes referred to as wire cable slings are more robust and durable than nylon slings and have higher temperature limits. There are many different types of wire rope slings and they all have their own purposes. For instance, the normal sling strength is based on the strength of the wire rope used in the sling. A sling angle is the angle measured between a horizontal line and the sling leg or body.

Wire rope slings are used extensively within the industrial lifting industry. Wire rope slings, sometimes referred to as wire cable slings are more robust and durable than nylon slings and have higher temperature limits. There are many different types of wire rope slings and they all have their own purposes. For instance, the normal sling strength is based on the strength of the wire rope used in the sling. A sling angle is the angle measured between a horizontal line and the sling leg or body.

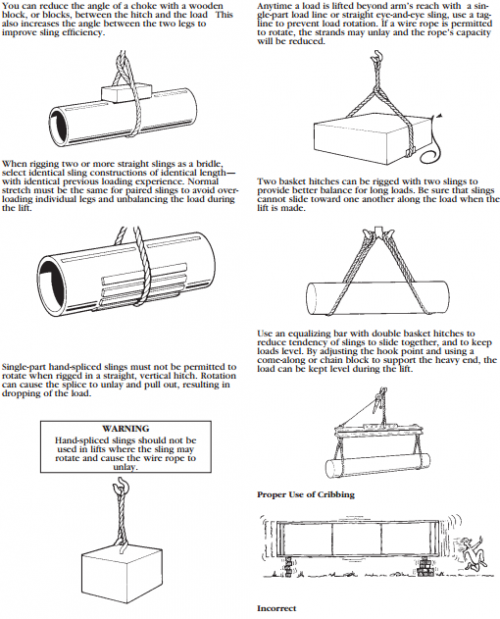

A nominal sling strength is based upon the nominal (catalog) rope strength of the wire rope used in the sling and other factors which affect the overall strength of the sling. These other factors include splicing efficiency, number of parts of rope in the sling, type of hitch (e.g., straight pull, choker hitch, basket hitch, etc.), diameter around which the body of the sling is bent (D/d) and the diameter of pin used in the eye of the sling.

Please download and familiarize yourself with all of the full wire rope slings specification PDF on this web page. CERTEX believes in supplying high quality wire rope slings and other quality products and the safety of use for all products.

Download Full Wire Rope Slings Specification PDF